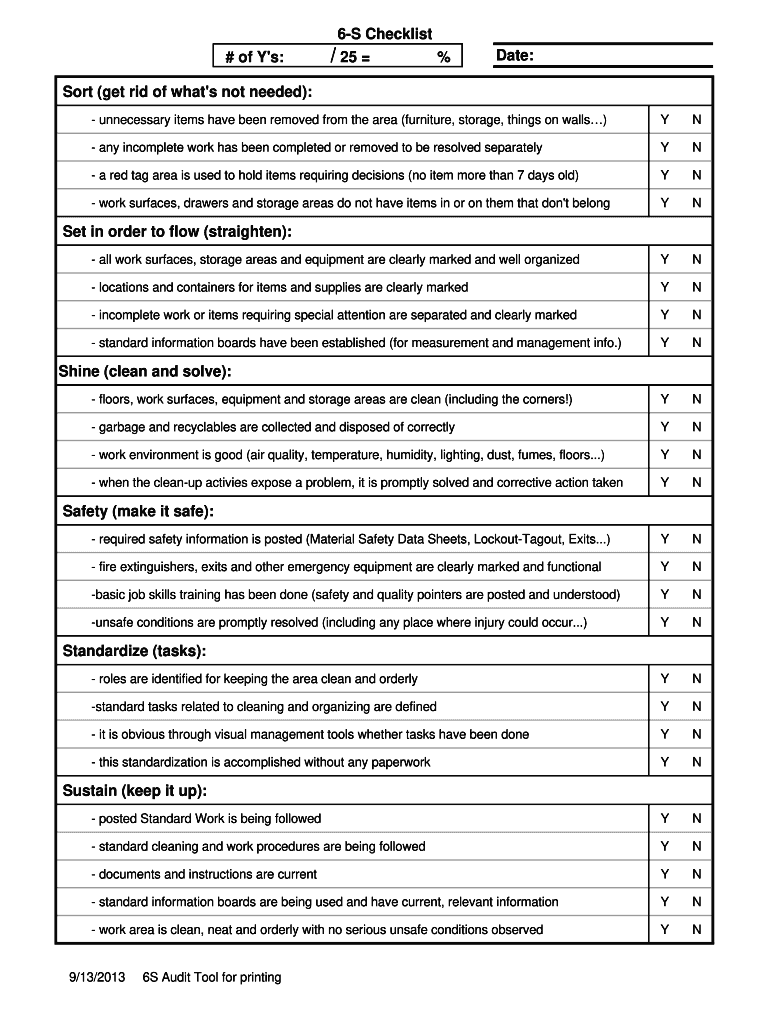

6S Cleaning Checklist Template

6S Cleaning Checklist Template - Implementing the 6s audit checklist can lead to reduced waste, increased productivity, improved safety, and enhanced employee morale. It also helps organizations achieve cost savings and. Remember, the goal is to create a checklist that is not only functional but also pleasant to look at. Browse the public library of over 100,000 free editable checklists for all industries. Our 6s safety audit checklist allowes you identify hazards or potential risks within your company. Use the 6s lean checklist to identify hazards or potential risks while performing tasks in the workplace. Use the 6s lean safety checklist to identify hazards or potential risks while performing tasks in the workplace. View and download manufacturing 6s audit for free. 6s cleaning checklist template use the 6s audit checklist for manufacturing to optimize workplace efficiency, safety, organization and cleanliness in line with the 6s method. Use this template periodically to inspect the quality and safety practices in your manufacturing, logistics and other work. Not only that, this checklist encourages a. A 6s audit checklist manufacturing is a powerful tool to help ensure manufacturing processes are running efficiently and safely. Use this template to apply the 6s method in your production. Implementing the 6s audit checklist can lead to reduced waste, increased productivity, improved safety, and enhanced employee morale. When you enjoy using your checklist, you're more likely to keep up with. 6s cleaning checklist template use the 6s audit checklist for manufacturing to optimize workplace efficiency, safety, organization and cleanliness in line with the 6s method. This document is a 6s audit checklist used to evaluate different departments at mmi industries based on 6s principles. With japanese origins, similar to kaizen and other lean initiatives, a 6s audit checklist is used to keep any given area safe, organized, clean and structured in a way that makes it easiest to. It also helps organizations achieve cost savings and. View and download manufacturing 6s audit for free. View and download manufacturing 6s audit for free. Browse the public library of over 100,000 free editable checklists for all industries. Take a photo of steps or activity conducted and generate report onsite. With japanese origins, similar to kaizen and other lean initiatives, a 6s audit checklist is used to keep any given area safe, organized, clean and structured in. It also helps organizations achieve cost savings and. Use the 6s lean checklist to identify hazards or potential risks while performing tasks in the workplace. This document is a 6s audit checklist used to evaluate different departments at mmi industries based on 6s principles. Use the 6s lean safety checklist to identify hazards or potential risks while performing tasks in. Conduct effective audits and inspections with the free checklist template of 6s audit checklist. Our 6s safety audit checklist allowes you identify hazards or potential risks within your company. Certainty’s 6s lean audit checklist helps you to identify areas for improvement, set priorities for your actions, and keep tabs on your progress. Use the 6s lean checklist to identify hazards. Browse the public library of over 100,000 free editable checklists for all industries. Get your pdf for free now! Use this template to apply the 6s method in your production. Implementing the 6s audit checklist can lead to reduced waste, increased productivity, improved safety, and enhanced employee morale. Conduct effective audits and inspections with the free checklist template of 6s. Browse the public library of over 100,000 free editable checklists for all industries. This document is a 6s audit checklist used to evaluate different departments at mmi industries based on 6s principles. Use this template periodically to inspect the quality and safety practices in your manufacturing, logistics and other work. Use this template to apply the 6s method in your. A 6s audit is basically a 5s audit with extra attention to safety. When you enjoy using your checklist, you're more likely to keep up with. This document is a 6s audit checklist used to evaluate different departments at mmi industries based on 6s principles. View and download manufacturing 6s audit for free. Take a photo of steps or activity. View and download manufacturing 6s audit for free. Browse the public library of over 100,000 free editable checklists for all industries. Use this template to apply the 6s method in your production. Get your pdf for free now! Remember, the goal is to create a checklist that is not only functional but also pleasant to look at. Conduct effective audits and inspections with the free checklist template of 6s audit checklist. A 6s audit checklist manufacturing is a powerful tool to help ensure manufacturing processes are running efficiently and safely. Use the 6s lean checklist to identify hazards or potential risks while performing tasks in the workplace. It also helps organizations achieve cost savings and. Improve continuously. With japanese origins, similar to kaizen and other lean initiatives, a 6s audit checklist is used to keep any given area safe, organized, clean and structured in a way that makes it easiest to. A 6s audit checklist manufacturing is a powerful tool to help ensure manufacturing processes are running efficiently and safely. Implementing the 6s audit checklist can lead. Browse the public library of over 100,000 free editable checklists for all industries. Certainty’s 6s lean audit checklist helps you to identify areas for improvement, set priorities for your actions, and keep tabs on your progress. With japanese origins, similar to kaizen and other lean initiatives, a 6s audit checklist is used to keep any given area safe, organized, clean. Use this template periodically to inspect the quality and safety practices in your manufacturing, logistics and other work. Use the 6s lean safety checklist to identify hazards or potential risks while performing tasks in the workplace. View and download manufacturing 6s audit for free. Certainty’s 6s lean audit checklist helps you to identify areas for improvement, set priorities for your actions, and keep tabs on your progress. Browse the public library of over 100,000 free editable checklists for all industries. Our 6s safety audit checklist allowes you identify hazards or potential risks within your company. Use this template to apply the 6s method in your production. Improve continuously cleanliness, order, safety, quality, and. Conduct effective audits and inspections with the free checklist template of 6s audit checklist. Browse the public library of over 100,000 free editable checklists for all industries. With japanese origins, similar to kaizen and other lean initiatives, a 6s audit checklist is used to keep any given area safe, organized, clean and structured in a way that makes it easiest to. By applying the 6s’ you will organize, eliminate unneeded materials and enable. Not only that, this checklist encourages a. Take a photo of steps or activity conducted and generate report onsite. Remember, the goal is to create a checklist that is not only functional but also pleasant to look at. A 6s audit is basically a 5s audit with extra attention to safety.6s Checklist Fill Online, Printable, Fillable, Blank, 41 OFF

6s Checklist Complete with ease airSlate SignNow

6s Audit Checklist PDF Personal Protective Equipment Safety

Checklist 6S PDF

6S Checklist Template

The 6S's of Warehouse Maintenance B.I.G. Logistics

6S Checklist Format Format Excel PDF Sample, 60 OFF

6s Lean Audit Checklist Template PDF Housekeeping Personal

6S Checklist Template

6S Checklist Template

6S Cleaning Checklist Template Use The 6S Audit Checklist For Manufacturing To Optimize Workplace Efficiency, Safety, Organization And Cleanliness In Line With The 6S Method.

A 6S Audit Checklist Manufacturing Is A Powerful Tool To Help Ensure Manufacturing Processes Are Running Efficiently And Safely.

Get Your Pdf For Free Now!

Implementing The 6S Audit Checklist Can Lead To Reduced Waste, Increased Productivity, Improved Safety, And Enhanced Employee Morale.

Related Post: